Description

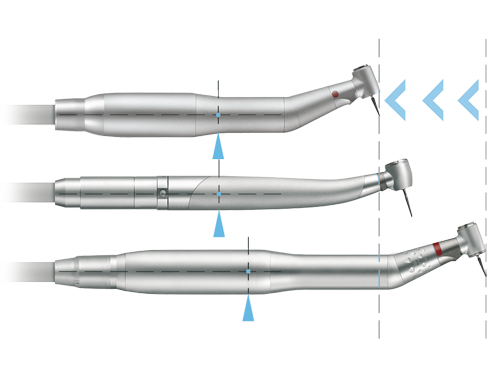

CA 1:1

HERITAGE OF RELIABILITY.

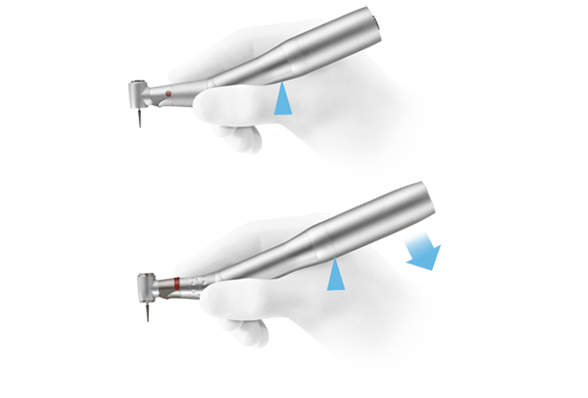

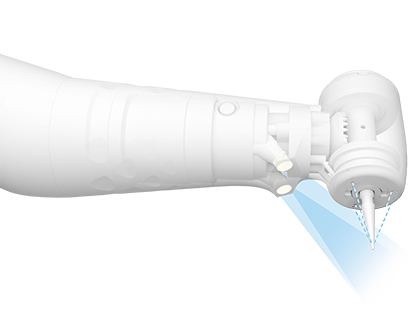

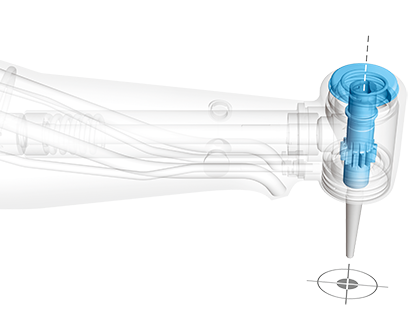

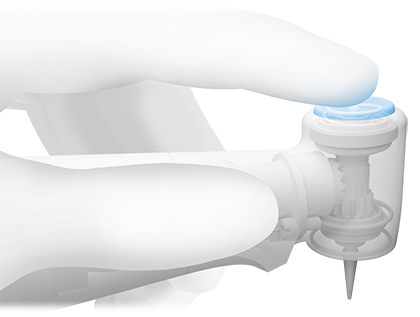

There are some devices still earning respect and admiration forty years in, and Bien-Air’s classic CA 1:1 and CA 1:5 electric handpieces are two of them. Forever evolving, their dominating productivity and remarkable durability make them the most popular models in the lineup. The series’ fully redesigned bur-locking and rotation drive mechanism ensures micron-precise concentricity and stability, while a 60 to 200,000 rpm speed range lets you complete the most intricate restorative work with incredible accuracy – and on your own terms. CA 1:1 and CA 1:5 epitomize the reliability and quality Bien-Air has built its reputation on.

Reviews

There are no reviews yet.