Description

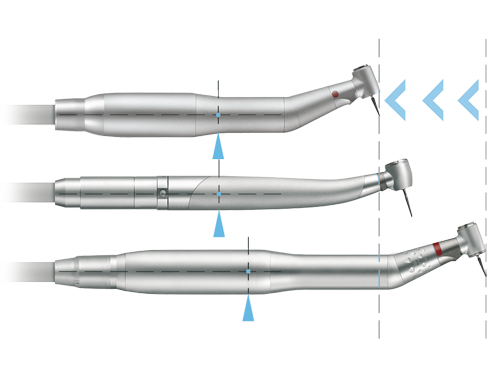

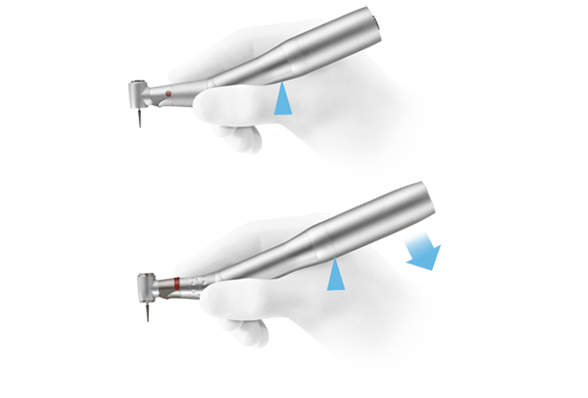

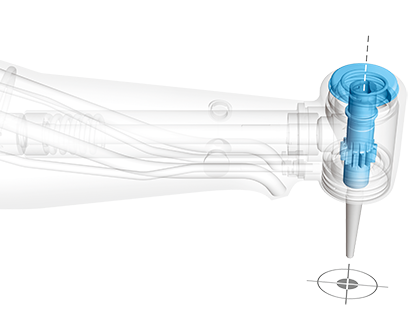

CA 20:1

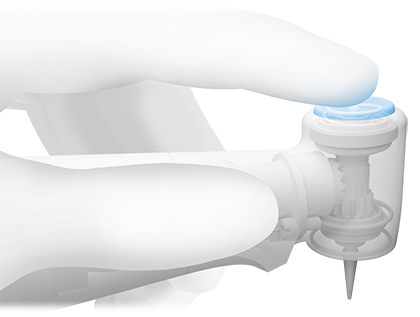

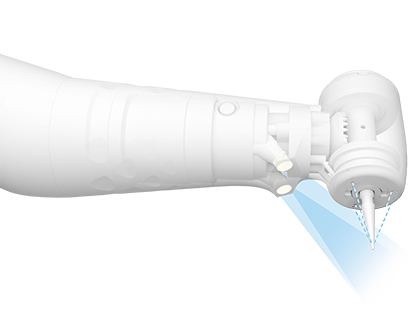

This contra-angle has an irrigation system which is internal to the instrument – a world first. So your grip is not impeded by the irrigation line. The jet of physiological liquid is projected onto the drill shaft itself,providing perfect cooling, particularly when using implant guides for insertions. The CA 20:1 has a miniature head and is the lightest on the market. In addition, its shafts and gears are machined in stainless steel with high resistance to saline solutions.

Reviews

There are no reviews yet.