Description

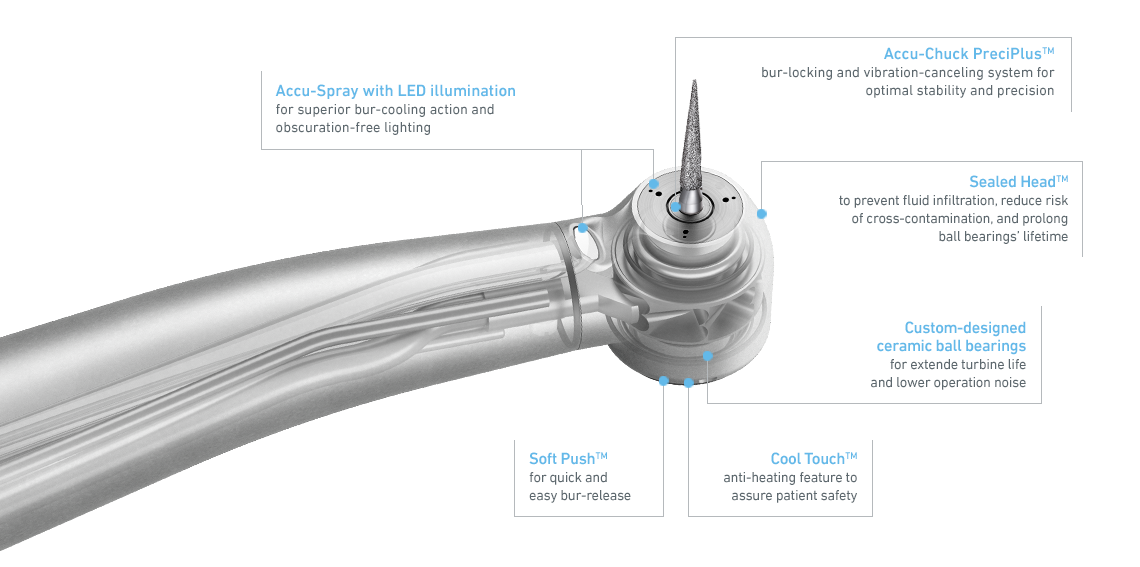

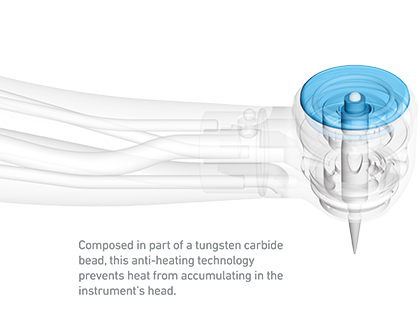

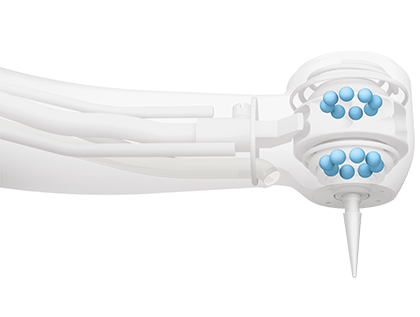

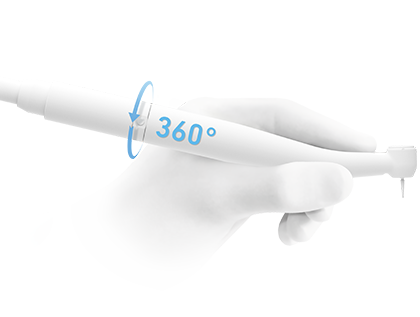

TORNADO X

ULTIMATE RELIABILITY

60 years of know-how and passion is the secret that leads Bien-Air Dental today to offer exceptionally reliable products. Discover all our expertise and attention to detail in the new TORNADO X turbine.

With 60 years of expertise, Bien-Air Dental offers and guarantees an outstanding level of reliability.

Reviews

There are no reviews yet.